Cov khoom xa khoom ntawm cov kab xev kub ua rau cov kab xev: qib kev txhim kho cov kev tswj hwm

Khoom cov tsis muaj cov khoom lag luam tseem ceeb

| Ntiag tug | Ib yam | TS150 | TS200 | TS250 | Ts300 | Ts350 | Ts400 |

|---|---|---|---|---|---|---|---|

| Qhov tuab | mm | 0.20 ~ 10.0 | 0.20 ~ 10.0 | 0.20 ~ 10.0 | 0.30 ~ 10.0 | 0.30 ~ 10.0 | 0.30 ~ 10.0 |

| Xim | - | Grey / xiav | Grey / xiav | Grey / xiav | Grey / xiav | Grey / Ntshav | Grey / Ntshav |

| Kev nyuaj | sc | 10 ~ 60 | 10 ~ 60 | 20 ~ 60 | 20 ~ 60 | 20 ~ 60 | 20 ~ 60 |

| Thermal conductivity | W / min k | 1.5 | 2.2 | 2.5 | 3.1 | 3.6 | 4.1 |

| Hluav taws kub tiv thaiv | UL - 94 | V0 | V0 | V0 | V0 | V0 | V0 |

| Lub Zog Hluav Taws Xob | Kv / hli | > 6.5 | > 6.5 | > 6.5 | > 6.5 | > 6.5 | > 6.5 |

| Lub zog tensile | MPa | 0.1 | 0.1 | 0.1 | 0.5 | 0.134 | 0.134 |

| Kua muag lub zog | N / hli | 1.5 | 1.5 | 1.5 | 0.4 | 0.279 | 0.279 |

| Ceev | g / cm3 | 2.5 | 2.5 | 2.6 | 2.8 | 3.0 | 3.3 |

| Nta Adhesion | Hlau Pob | > 10 # | > 10 # | > 10 # | > 10 # | > 10 # | > 10 # |

| Lub ntim tsis kam | mω / m | 1 * 10 ^ 13 13 | 1 * 10 ^ 13 13 | 1 * 10 ^ 13 13 | 1 * 10 ^ 13 13 | 1 * 10 ^ 13 13 | 1 * 10 ^ 13 13 |

| Nto tsis kam | Ω | 1 * 10 ^ 12 | 1 * 10 ^ 12 | 1 * 10 ^ 12 | 1 * 10 ^ 12 | 1 * 10 ^ 12 | 1 * 10 ^ 12 |

| Tsev hauj lwm kub | ℃ | - 40 ~ 200 | - 40 ~ 200 | - 40 ~ 200 | - 40 ~ 200 | - 40 ~ 200 | - 40 ~ 200 |

| Cov ntsiab lus sixiane | ppm | ||||||

| Elongation | % | 50% | 50% | 50% | 50% | 50% | 50% |

Cov Khoom Lag Luam Khoom Tshwj Xeeb

| Ntiag tug | Ib yam | Ts500 | Ts600 | Ts700 | TS800 | Ts1000 | TS1300 |

|---|---|---|---|---|---|---|---|

| Qhov tuab | mm | 0.30 ~ 10.0 | 0.80 ~ 10.0 | 0.80 ~ 10.0 | 0.80 ~ 10.0 | 1.0 ~ 10.0 | 0.8 ~ 10.0 |

| Xim | - | Xim txho | Xim txho | Xim txho | Xim txho | Grey / xiav | Xim txho |

| Kev nyuaj | sc | 20 ~ 60 | 20 ~ 60 | 30 ~ 60 | 30 ~ 60 | 10 ~ 60 | 30 ~ 60 |

| Thermal conductivity | W / min k | 5 | 6.1 | 7 | 8 | 10 | 13 |

| Hluav taws kub tiv thaiv | UL - 94 | V0 | V0 | V0 | V0 | V0 | V0 |

| Lub Zog Hluav Taws Xob | Kv / hli | > 6.5 | > 6.5 | > 6.5 | > 6.5 | > 6.5 | > 6.5 |

| Lub zog tensile | MPa | 0.091 | 0.091 | 0.1 | 0.085 | 0.07 | 0.065 |

| Kua muag lub zog | N / hli | 0.49 | 0.45 | 0.8 | 0.35 | 0.3 | 0.28 |

| Ceev | g / cm3 | 3.2 | 3.3 | 3.3 | 3.5 | 3.5 | 3.3 |

| Nta Adhesion | Hlau Pob | > 10 # | > 10 # | > 10 # | > 10 # | > 10 # | > 7 # |

| Lub ntim tsis kam | mω / m | 1 * 10 ^ 13 13 | 1 * 10 ^ 13 13 | 1 * 10 ^ 13 13 | 1 * 10 ^ 13 13 | 1 * 10 ^ 13 13 | 1 * 10 ^ 13 13 |

| Nto tsis kam | Ω | 1 * 10 ^ 12 | 1 * 10 ^ 12 | 1 * 10 ^ 12 | 1 * 10 ^ 12 | 1 * 10 ^ 12 | 1 * 10 ^ 12 |

| Tsev hauj lwm kub | ℃ | - 40 ~ 200 | - 40 ~ 200 | - 40 ~ 200 | - 40 ~ 200 | - 40 ~ 200 | - 40 ~ 200 |

| Cov ntsiab lus sixiane | ppm | ||||||

| Elongation | % | 50% | 50% | 50% | 50% | 50% | 50% |

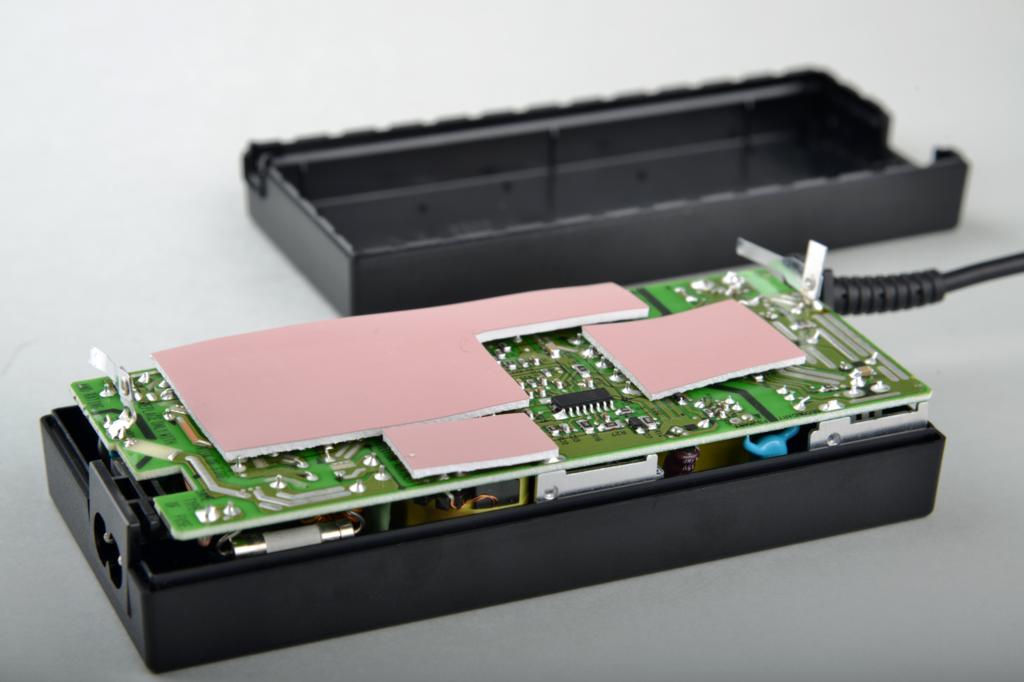

Cov khoom lag luam tsim khoom

Kev tsim kho cov kab xev cuam tshuam nrog ntau cov kauj ruam tseem ceeb los xyuas kom meej cov cua sov thiab nplaum ua tau zoo. Thaum pib, siab - purity thermally cov ntaub ntawv zoo li txhuas oxide, boron nitride, lossis graphite yog xaiv thiab ua kom zoo milled rau hauv cov hmoov av. Cov hmoov no tau sib xyaw ua ke rau hauv cov polymer matrix, feem ntau silicone lossis acrylic, los ua cov tshuaj lom neeg uas ua kom haum. Ua raws li qhov no, cov ntawv sau tau raug rau cov txheej txheem txheej txheej uas nws tau thov rau daim ntawv sau lossis zaj duab xis, siv precision txheej tshuab uas ua rau tswj cov tuab thiab kev sib dhos.

Muaj ib zaug npog, cov khoom undergoes ib tug txheej txheem kho qhov twg nws yog rhuab kom qhib cov khoom nplaum thiab ua tiav cov khoom siv xav tau muaj zog. Cov khoom siv kho tau yog ces txias thiab txiav mus rau hauv cov kev ua kom ntev, xws li cov ntawv txheeb, yob - Txiav qhov kawg - Siv Yuav Tsum Tau Siv. Kev ntsuas kev tswj hwm zoo, suav nrog kev xeem rau thermal conductivity, adhesion lub zog, thiab cov hluav taws xob ua kom ntseeg tau tias cov qauv kev lag luam nruj. Lub tiav cov cua kub ua kom cov kab xev yog li ntawd ntim thiab sau npe rau kev faib tawm.

Khoom Daim Ntawv Thov

Cua sov cov kab xev qhia pom dav dav thoob plaws ntau kev lag luam vim nws ntau yam cua sov kev tswj hwm kev tswj hwm lub peev xwm. Nyob rau hauv cov khoom siv hluav taws xob, nws yog qhov ntau siv rau kev sib tham thaum tshav kub kub tog rau CPUs, Gpus, fais fab transistors, thiab LEDs. Cov khoom siv no tsim cua ua haujlwm ntau lub sijhawm ua haujlwm, thiab siv tau cov kev tswj hwm thermal yog qhov tseem ceeb rau kev ua kom muaj kev ua tau zoo thiab tiv thaiv kev kub ntxhov. Daim kab xev tsis tsuas yog ua kom yooj yim hloov tshav kub tab sis kuj muab hluav taws xob rwb thaiv tsev, kom muaj kev nyab xeeb thiab txhim khu kev qha ntawm cov khoom siv hluav taws xob.

Nyob rau hauv kev lag luam automotive, tshwj xeeb tshaj yog nyob rau hauv cov tsheb hluav taws xob (EVS), cua sov ua si lub luag haujlwm tseem ceeb hauv roj teeb cov cua sov kev tswj hwm. Nws kom ntseeg tau tias cov roj teeb pob kom ruaj khov kho qhov kub, yog li ua tau zoo thiab txuas lub roj teeb lub neej. Daim kab xev kuj tseem siv tau kom muaj qhov kub thiab txias - rhiab sensors thiab cov txuas tsis pub dhau lub cav bay, qhov twg ua rau muaj huab cua sov huab cua ntau. Hauv ib daim ntawv thov aerospace, qhov kev thov rau lub teeb thiab siab - Kev ua kom sov cov khoom siv hluav taws xob ua rau cov khoom siv hluav taws xob ua rau kev ua haujlwm hauv dav hlau, ua kom tiav txoj haujlwm txhim khu kev qha raws li cov xwm txheej nyuaj.

Khoom tom qab - muag kev pabcuam

Peb muaj cov kev pabcuam tom qab - muag kev pabcuam kom ntseeg tau tias peb cov neeg muas zaub tau txaus siab nrog lawv cov kev yuav khoom. Peb cov kev pabcuam suav nrog kev txhawb nqa kev txhawb nqa los pab nrog cov khoom lag luam, kev cob qhia khoom, thiab daws cov teeb meem uas tuaj yeem tshwm sim thaum siv sijhawm. Ib qho ntxiv, peb muab kev tiv thaiv kev tiv thaiv thiab hloov cov kev xaiv rau cov khoom tsis khoom. Peb cov neeg tau mob siab pab neeg yog ib txwm npaj los pab nrog cov lus nug thiab daws teeb meem sai sai rau peb cov neeg siv khoom.

Cov Tsheb Thauj Mus Los

Peb cov cua sov coj mus rau cov kab xev daim ntaub nyias muaj ntim cov khoom lag luam kom ntseeg tau tias lawv ncav cuag peb cov neeg siv khoom hauv cov kab mob zoo meej. Peb siv cov ntaub ntawv ntim ruaj khov thiab cov tswv yim los tiv thaiv cov khoom lag luam los ntawm kev puas tsuaj thaum pib. Peb muab ntau txoj kev xaiv thauj khoom rau cer cer cater rau rau cov kev xav tau sib txawv, suav nrog cov kev pabcuam thiab nrawm nrawm. Peb cov neeg koom tes tau hais tawm tau hais txog thiab kev paub hauv kev siv cov ntaub ntawv muaj kev lag luam, ua kom tiav raws sijhawm thiab txhim khu kev qha rau peb cov neeg thoob ntiaj teb.

Cov khoom lag luam zoo

- Yooj yim ntawm daim ntawv thov: Tus neeg siv - Tus phooj ywg thiab yooj yim txiav rau cov duab uas xav tau thiab ntau thiab tsawg.

- Hluav taws xob rwb thaiv tsev: tiv thaiv luv luv ncig thaum ua kom muaj txiaj ntsig zoo thermal kev tswj hwm.

- Versilility: cov lus qhia rau ntau qhov chaw sib txawv nrog rau cov hlau, plastics, thiab ceramics.

- Txhim kho kev cia siab: txhim kho kom muaj kev cia siab thiab lub neej lub zog hluav taws xob.

Khoom Muag FAQ

- Dab tsi yog cov thermal conductivity khwv ntawm koj cov cua sov ua daim kab xev?

Peb cov ntaub ntawv cua sov muaj cov thermal conductivity khwv ntawm 1.5 w / mk txog 13 w / mk, nyob ntawm cov khoom lag luam tshwj xeeb thiab cov qauv. - Yuav siv cov kab xev kom sov puas tau rov qab siv dua?

Yog lawm, ntau ntawm peb cov vaskowiving kub yog tsim los ua kom rov ua tau, tso cai rau kev rov ua haujlwm yog tsim nyog. Txawm li cas los xij, kev saib xyuas yuav tsum tau noj thaum tshem tawm kom muaj kev ua tiav zoo. - Puas yog tus kab xev yooj yim txiav thiab siv?

Kiag li. Peb cov ntaub ntawv kub ua tau yooj yim txiav rau cov duab yam uas xav tau thiab muaj cov kev cai tswj hwm kev tswj hwm zoo li cov pastric thermal. - Koj cov khoom pov thawj li cas?

Peb cov cua sov ua tau pov thawj tau lees paub los ntawm UL, ncav cuag, ROHS, ISO 9001, thiab ISO 16949, kom lawv tau raws li cov qauv siab thiab kev nyab xeeb. - Koj puas tuaj yeem siv cov kab xev cua sov siv nyob rau ib puag ncig kub -?

Yog lawm, peb cov chav kub ua kom pom kev yooj yim yog tsim los ua kom muaj ntau yam kub los ntawm - 40 ℃ rau 200 ℃, ua rau lawv haum rau cov ntawv thov kub siab. - Koj ua li cas thiaj paub tias qhov zoo ntawm koj cov khoom?

Peb ua kev ntsuas nruj kev tswj hwm ntawm ntau theem ntawm kev tsim khoom rau thermal conductivity, adhesion lub zog, thiab rwb thaiv tsev hluav taws xob kom ntseeg tau tias peb cov khoom lag luam raws cov qauv kev lag luam. - Qhov kev txiav txim yam tsawg kawg nkaus rau koj cov kev hloov pauv kub?

Qhov kev txiav txim yam tsawg kawg nkaus rau peb cov kev ntsuas kub yog 1000 daim. Peb tseem muab kev xaiv kev yuav khoom rau qhov yuav tsum tau ua. - Koj puas tuaj yeem muab cov khoom lag luam ncaj ncees raws cov cai tshwj xeeb?

Yog lawm, peb muab cov cua sov customized tapes raws cov neeg siv khoom thiab kos duab kom tau raws li cov cai. Thov hu rau peb nrog koj cov lus qhia tshwj xeeb rau kev pab ntxiv. - Koj cov nqe lus them nqi yog dab tsi?

Peb muab cov ntsiab lus them nqi hloov kho kom haum rau peb cov neeg siv khoom xav tau. Thov hu rau pab pawg muag cov ntaub ntawv kom ntxaws txog cov kev xaiv them nyiaj. - Koj puas muab tom qab kev txhawb nqa muag?

Yog, peb muab kev muag khoom suav nrog kev lag luam suav nrog kev pabcuam kev pabcuam, kev tiv thaiv kev tiv thaiv, thiab hloov cov kev xaiv rau cov khoom puas.

Khoom Kub Khoom Kub

- Qhov tseem ceeb ntawm kev tswj thermal hauv electronics

Raws li cov khoom siv hluav taws xob ua ntau dua thiab kev cog lus, tswj cov kub dissipation ua kom muaj kev nce qib. Kev tswj hwm thermal muaj txiaj ntsig zoo uas cov khoom lag luam ua haujlwm nyob rau hauv cov ntsuas kub muaj kev nyab xeeb, txhim kho kev ua tau zoo thiab kev ntseeg tau. Cov khoom lag luam zoo li peb cov kab xev cua sov muab cov tshuaj kub thiab tus neeg siv khoom siv ua kom muaj kev phom sij

- Vim li cas thiaj xaiv cov kab xev kub ua kom kub tshaj?

Thaum ob qho tib si kub ua cov kab xev thiab thermal paste pab lub hom phiaj ntawm kev hloov pauv ntawm cua sov, daim kab xev muaj ntau qhov zoo. Nws yooj yim dua rau kev thov, muab tuab tuab, thiab tuaj yeem siv rov qab. Ib qho ntxiv, cov kab xev kom sov muab cov rwb thaiv hluav taws xob, txo qhov kev pheej hmoo ntawm cov voj voog luv luv. Peb lub cua sov coj cov kab xev yog tsim los muab cov thermal condal conductivity thiab durability, ua rau nws xaiv tau xaiv ntau rau ntau daim ntawv thov.

- Lub luag haujlwm ntawm cov kab xev cua sov hauv cov tsheb hluav taws xob

Hauv cov tsheb hluav taws xob, tswj cov roj teeb kub yog qhov tseem ceeb rau kev ua tau zoo thiab thiav. Tshav kub ua cov kab xev ua lub luag haujlwm tseem ceeb hauv cov roj teeb lub tshuab tswj kev tswj hwm, kom muaj kev tiv thaiv ruaj khov thiab tiv thaiv kev kub ntxhov. Peb qhov siab - Kev ua yeeb yam kub kub tau tsim los ua kom tau raws li qhov xav tau ntawm kev tswj hwm tsheb, muab cov khoom siv hluav taws xob thermal.

- Nkag siab ua cov txheej txheem tsim khoom ntawm cov ntaub nplaum

Kev tsim kho cov kab xev cuam tshuam nrog kev xaiv siab - Purity thermally cov ntaub ntawv, sib xyaw ua ke rau hauv ib lub polymer matrix, thiab siv cov tshuaj polymer rau hauv ib substrate. Txoj kev no ua kom ntseeg tau tias cov kab xev tso rau cov cua sov zoo dua thiab cov khoom ua kom muaj txiaj ntsig. Peb cov ncauj lus ntxaws tswj kev tswj kom ntseeg tau tias txhua lub pob cua sov ua kom pom kev nruj kev lag luam kev lag luam, kev ua tau zoo hauv kev ua lag luam.

- Kev nrhav kev daws teeb meem

Nrog kev nce qib nruam hauv cov khoom siv hluav taws xob, qhov xav tau ntawm cov kev tswj thermal kev tswj hwm tau loj hlob. Kev nrhav cov ntaub ntawv thiab cov txheej txheem tsim qauv tau ua rau kev txhim kho cov cua sov ua cov thermal conductivity thiab durability. Peb lub tuam txhab yog nyob rau ntawm qhov laj thawj ntawm kev nrhav cov khoom tshiab thiab cov txheej txheem ntau lawm ua kom tau raws li cov kev xav tau ntawm peb cov neeg siv khoom.

- Qhov cuam tshuam ib puag ncig ntawm cov ntaub ntawv tswj hwm

Raws li qhov kev thov rau cov khoom tswj thermal

Duab piav qhia